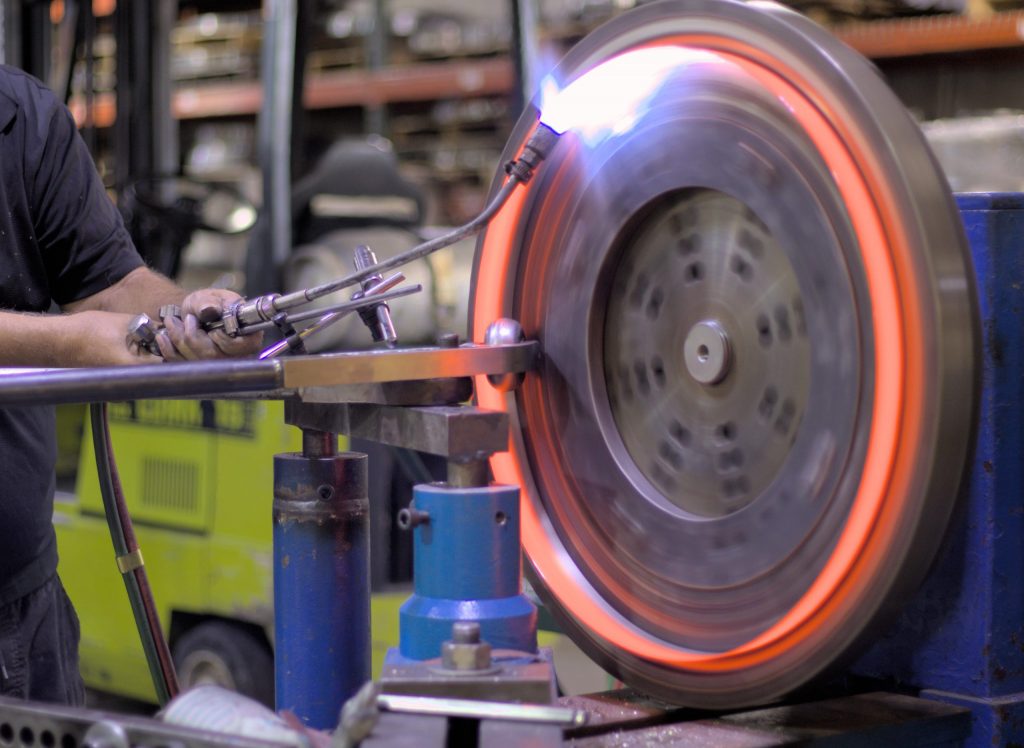

Metal SPinning Services

Your key to complex and precise metal parts! Utilize our metal spinning services, where traditional craftsmanship meets advanced technology. We specialize in forming symmetrical hollow geometries such as cylinders, cones, or hemispherical shapes from exotic alloys like Inconel™, Haynes™, Waspaloy™, and Rene™ Alloys. Our well-equipped facilities can spin shapes up to 72″ in diameter, providing cost-effective, durable solutions for your needs.

- Expert handling of exotic alloys

- Capacity to spin large diameters

- Precision craftsmanship and accuracy

- Complementary finishing services

- Rapid prototyping abilities

- Cost-effective, long-lasting solutions

Get a free quote

Our process

Flowless and reliable process

Experience the best in the industry. We have designed a seamless process for our metal spinning service that ensures quality, precision, and quick turnaround.

01.

Project Planning

Your vision, our expertise! We work with your team to understand the needs and design a plan that meets those needs while maximizing manufacturability.

02.

Prototyping

Turning ideas into reality! Our production team will collaborate with your R&D team to create custom tooling and develop prototypes.

03.

Production

Quality products, every time! Our wide range of in-house services provides a complete solution to your manufacturing needs, ensuring a smooth transition from prototype to full-scale production.

Metal Spinning Experts

Discover the premier provider of metal spinning services at KIHM Metal Technologies. Our advanced processes, precision craftsmanship, and use of exotic alloys set us apart in the industry. If you’re searching for expert solutions in “Metal Spinning,” “Exotic Alloy Metal Spinning,” “Inconel Metal Spinning,” or “Precision Metal Spinning,” you’ll find that KIHM has the knowledge, skills, and technology to bring your vision to life.

We specialize in creating symmetrical hollow geometries such as cylinders, cones, and hemispherical shapes with sizes up to 72″ in diameter. For industries like aerospace, defense, and power generation, we offer prototyping and full-scale production capabilities that ensure quality and cost-effectiveness. Experience our seamless process from project planning to production.

Start your journey with KIHM today – the leader in metal spinning services.