Laser Services

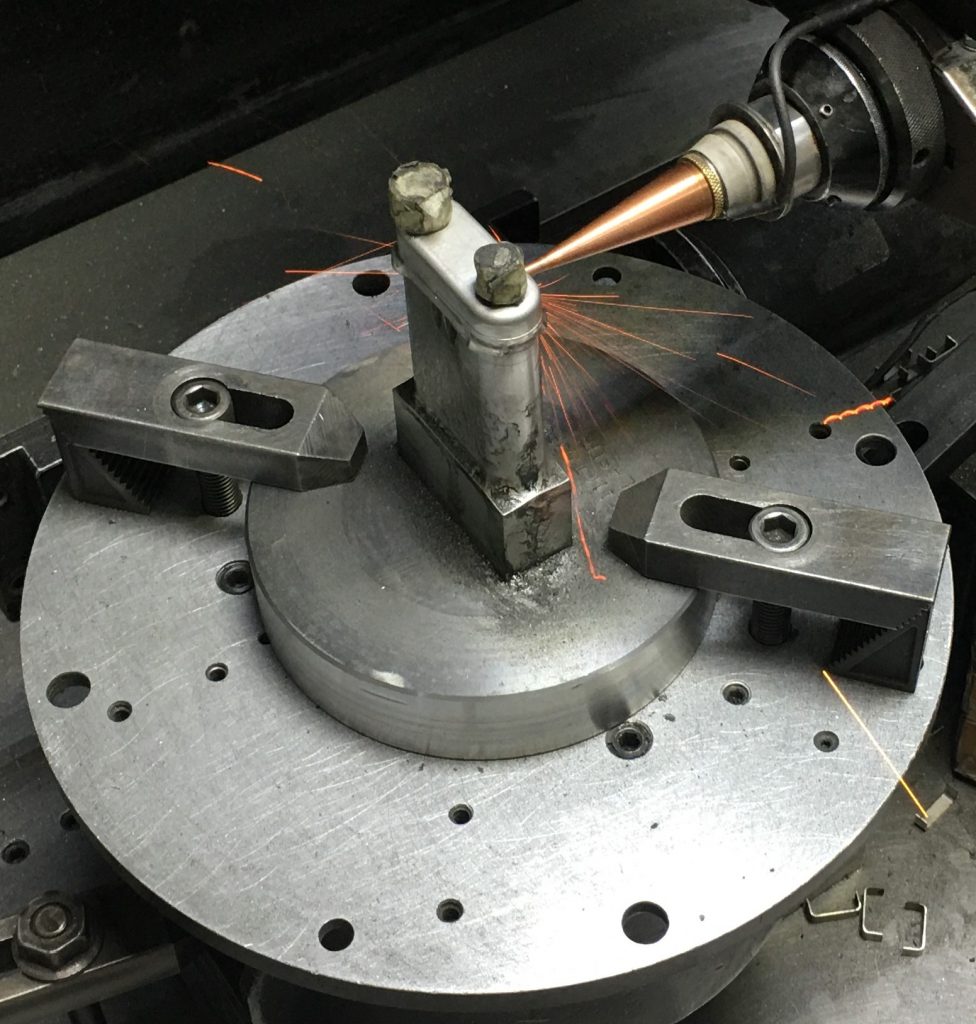

Elevate the precision and speed of your production with our NADCAP approved 6-axis CO2 and 6-axis Fiber Laser technologies. At KIHM, we’re committed to complementing our hydroforming and metal spinning processes with superior laser services that adhere to the highest standards of quality and efficiency.

- Cutting speed and accuracy

- Complex trimming capabilities

- Eliminates need for secondary processing

- Handles a wide variety of materials

- Integrated with all of our services

- Cost-effective, long-lasting solutions

Get a free quote

Our process

Flawless and reliable process

Laser services at KIHM are meticulously designed to integrate seamlessly into our process, providing an additional layer of precision and quality.

01.

Consultation and Planning

Understanding your needs is our priority. We’ll discuss the specifics of your project and how our laser services can enhance it.

02.

Laser Process

Our 6-axis CO2 and Fiber Laser technology swiftly and accurately cuts your chosen material, even with complex geometry.

03.

Production

Post-laser process, we conduct stringent quality checks to ensure accuracy and precision before delivering your final product.

Laser CUtting Experts

Trust in KIHM’s laser services to bring an elevated level of precision, speed, and quality to your production process. If you need accurate trimming for formed metal parts or complex geometries, our technology and expertise have got you covered. Start your journey with KIHM today – the leader in laser services.